A brief explanation of sake brewing

The list of ingredients is simple: water, rice and koji (rice malt). The spring water is sourced from the Northern Japanese Alps, with highest quality sake rice being grown locally for us.

The koji is grown within our facility to enable careful control of its unique characteristics. The clear air and the extremes of temperature essential for sake brewing occur in Azumino, yielding a premium sake loved by enthusiasts.

Stages of production:

1. Rice polishing: the grains are milled to remove unnecessary parts.

2. Washing/soaking: any remaining bran is removed and the rice is left to absorb water.

3. Steaming: effective fermentation requires rice grains to be hard on the outside and soft inside, hence the steaming process.

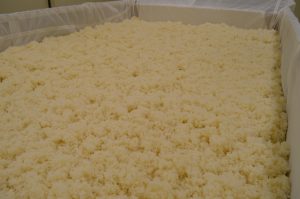

4. Koji making: koji mould spores are sprinkled onto the steamed rice and allowed to grow.

5. Shubo (yeast starter) making: shubo is made using water, koji, steamed rice and yeast.

6. Moromi (the main mash) making: moromi is made by putting water, koji and shubo into a fermentation tank. The volume is increased by adding the ingredients usually in three stages.

7. Pressing: the moromi is pressed in order to separate the sake and the kasu (lees).

8. Storage: the post production process includes pasteurisation, filtration, dilution and removal of sediment (ori-biki) in order to help stabilise the sake.